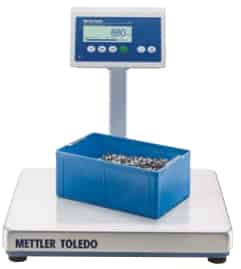

Piece Counting Machine – METTLER TOLEDO | Capacity 0.6 kg to 35 kg

99 in stock

Counting scales are used in different industries including automotive parts manufacturing, electronics, plastic or metal components production, paper manufacturing, or distribution warehouses. Accurate and efficient material management is the basis for successful, profitable production. METTLER TOLEDO counting scales can be easily incorporated into inventory management systems. That increases process reliability and productivity while efficiently controlling incoming and outgoing goods.

Get Free Delivery & Installation of all Weighing Scale in Only Delhi NCR – Noida, Greater Noida, Ghaziabad, Delhi, Gurugram, and Meerut (Note* – UP Scales don’t provide delivery & installation in outer Delhi NCR).

[caldera_form id=”CF5cbeab187482a”]

Piece Counting Machne

What is Piece Counting Machine?

Counting scales are used in different industries including automotive parts manufacturing, electronics, plastic or metal components production, paper manufacturing, or distribution warehouses. Accurate and efficient material management is the basis for successful, profitable production. METTLER TOLEDO counting scales can be easily incorporated into inventory management systems. That increases process reliability and productivity while efficiently controlling incoming and outgoing goods.

Every Piece Counts For Your Profit

1.) Material Receiving:-

Regardless of the size or number of incoming items counting scales verify the quantities received and provide accurate results in less time. Barcode scanners recall article information for immediate counting and transactions are stored in the scale embedded database for statistical analysis.

2.) Warehousing

Smart weighing and counting solutions keep track of stock movements, ensure flawless goods storage and help you avoid out-of-stock situations through direct integration into ERP systems. Mobile counting scales facilitate and speed up commissioning

3.) Production

Process automation and fast user guidance are essential to increase production efficiency and consistency. Semi-automated counting solutions assure efficient packaging right in production. Parts required for assembly are rapidly and precisely counted.

4.) Logistics & Shipping

Counting solutions assure that customer orders are accurately filled with exactly the right number of pieces, on time, and with the required labels and documentation.

Easy Operation Avoid Errors, Speed up Processes

Straightforward manual operation increases efficiency and accuracy in piece counting. METTLER TOLEDO scales feature advanced, easy to use counting applications. Operators just have to count the sample pieces, place them on the platform, press the predefined sample key, and start counting immediately.

1.) Avoid Errors

Intuitive user menus prevent operator errors and fatigue during routine tasks. Configurable softkeys allow fast access to key functions at a keystroke. Users are guided through the counting task in their language.

2.) Increase Speed

While counting pieces using a weighing system, operators typically have to concentrate intensely on the terminal display, slowing down their process. The colorWeight® function indicates, using different colors when the target is reached. This spares the operator’s concentration, speeds up the task, and saves time and money.

3.) Save Time

In order to reduce wasteful transportation time, distances between the picking place and the counting scale need to be reduced. Mobile scales with rechargeable batteries and wireless communication do a perfect job. For further comfort and to ease operators’ work the best ergonomic position of the counting scale can be chosen: compact, with column or table model.

Key Features & Benefits Piece Counting Machine :

- Fast access to key functions at a keystroke

- Easy database entry or recall with a barcode scanner or external keyboard

- Immediate indication of the target count is reached with colorWeight® display

- Selectable languages: English, Chinese, German, Spanish, French, Italian

- User profiles with dedicated functions such as assigned softkeys, language, user prompting or locked hard keys

Reduce Errors when Determining Average Piece Weights

Counting large quantities for reference (sample) determination by hand is tedious and opens the possibility for errors. However, sampling 30 or more parts increases counting accuracy. With the Automatic Reference Optimization feature, the scale assists the user in achieving a more accurate result with fewer errors. The operator hand counts 10 pieces and establishes the average piece weight. Then the operator places a few more pieces on the scale after which the Reference Optimization function will automatically recalculate the more accurate average piece weight.

Integrated Data Management Analyze, Trace, and Document

Efficiently counting thousands of parts demands the smart handling of numerous data points. Facilitate your daily counting jobs with counting scales featuring powerful databases with transaction memories that record all counting results for analysis and various printing options.

- Easy Data Analysis and Full Traceability:- Simplify monitoring and analyzing of weighing data with configurable databases. Analyze and trace all counting results in a transaction memory including date/time and operator ID. Benefit from a scale embedded or central (host) article database for up to 30,000 articles. Easily import or export data from the scale to Microsoft® Excel®.

- Fast Data Handling – Gain efficiency by connecting barcode scanners to automatically recall article information, such as average piece weight and directly start with counting. Connect the scale to another IT system, such as SAP, or import/ export article or transaction data with the USB memory stick, Ethernet, or wireless communication. Easily configure the scale and database on a PC.

- Facilitated Documentation – Customized labeling and full result documentation are key to fulfilling your customer’s needs or to comply with industry standards such as Odette, AIAG, or Galia. METTLER TOLEDO offers integrated printing solutions tailored to your application. Different formats can be defined including barcodes, article number, date, time, or customer logo. Whether you have to print labels, strips, or forms we provide a solution.

Key Features & Benefits:

- Scale embedded or central database for up to 30,000 articles.

- Transaction memory to easily monitor all counting results.

- Easy import/export databases and transaction data to Microsoft® Excel® for further statistical analysis.

- Connectivity to external IT systems in various ways.

- Pre-defined and user-definable printing templates.

- PC-software DatabICS to easily configure the scale.

Automate Your Counting Task

Reduce inefficient transportation to packaging stations and significantly reduce your staff’s involvement in parts counting with semi-automated counting directly at the production machine. Scales can control third party devices such as conveyor belts and stop or redirect parts filling as soon as the target piece count is reached. They also can alert operators by controlling external light or audible alarms. Tolerance such as target count or the average piece weight can be automatically called up from the article database by simply scanning a barcode or selecting an article ID.

Accuracy Counts Reliable Results from the Start

The concept of piece counting with a scale is quite simple. Counting accurately and efficiently can be a challenge. Errors occur when various factors influence the counting process, such as piece weight variation. Proper sampling and high-precision reference scales deliver accurate quantities from the start.

- Dealing with Piece Weight Deviation – Piece weight deviation is one of the most frequent sources of counting errors. Piece weights can differ due to the use of different machines, tool wear, raw material inconsistencies, or changing environmental conditions. If parts have a high deviation of more than 1 percent, the counting error can be cut in half by increasing the number of reference (sample) parts for example from 10 to 30 pieces.

- Highest Accuracy for Reliable Results – Accurate average piece weight determination is dependent on the appropriate counting resolution of the counting scale. To achieve a high counting resolution, the quality of the weighing electronics in terms of repeatability needs to be superior. METTLER TOLEDO counting scales feature proven counting resolutions of up to 1,200,000d, allowing minimum reference weights1) from 0.05 g with a process tolerance of 1%.

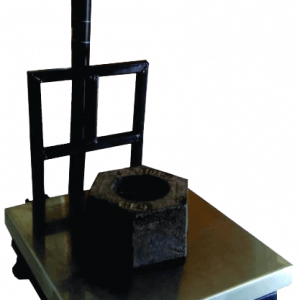

- Precise Counting from 1 mg to 3,000 kg – The lightest and heaviest parts influence the type of counting scales required. When counting a variety of parts, a two-scale system provides accuracy and flexibility. To precisely determine the average piece weights, connect a 0.1 mg reference scale, and count small pieces on a 0.6 kg to 6 kg scale. For medium weights, connect a bench scale up to 600 kg, and for heavyweights, use a floor scale for up to 3,000 kg.

Complete Offering High Throughput and Consistency

Speed counts in today’s competitive environment. Manufacturers must not only deliver error-free, high-quality products but also need to produce on time. Benefit from a complete counting scale portfolio with intuitive user menus facilitating your daily counting jobs. High-precision weighing technology delivers consistent results.

| Counting Weighing Scale | |||

|---|---|---|---|

| Capacity | Readability | Minimum Reference Weight |

Minimum Average Piece Weight |

| 0.6 kg | 0.001 g | 0.05 g | 0.005 g |

| 0.12/0.6 kg | 0.001/0.01 g | 0.05 g | 0.005 g |

| 3 kg | 0.01 g | 0.5 g | 0.05 g |

| 0.6/3 kg | 0.01/0.1 g | 0.5 g | 0.05 g |

| 6 kg | 0.01 g | 0.5 g | 0.05 g |

| 1.2/6 kg | 0.01/0.1 g | 0.5 g | 0.05 g |

| 6 kg | 0.1 g | 0.5 g | 0.05 g |

| 1.2/6 kg | 0.1/1 g | 0.5 g | 0.05 g |

| 3 kg | 0.5 g | 2.5 g | 0.25 g |

| 6 kg | 1 g | 5 g | 0.5 g |

| 15 kg | 0.1 g | 5 g | 0.5 g |

| 3/15 kg | 0.1/1 g | 5 g | 0.5 g |

| 35 kg | 0.1 g | 5.8 g | 0.58 g |

| 7/35 kg | 0.1/1 g | 5.8 g | 0.58 g |

| 15 kg | 2 g | 12.5 g | 1.25 g |

| 35 kg | 5 g | 30 g | 3 g |

Get Free Delivery, Installation & COVID-19 Guidelines

Get Free Delivery & Installation of all Weighing Scale in Only Delhi NCR – Noida, Greater Noida, Ghaziabad, Delhi, Gurugram, and Meerut (Note* – UP Scales don’t provide delivery & installation in outer Delhi NCR).

Our Delivery & Installation Engineers follow all COVID-19 guidelines while delivering & Installation of Weighing Scales given by the Indian Health Ministry and World Health Organization.

Specifications

| Applications | Counting, Totalizing, Over/Under Checkweighing/Counting, Simple Weighing |

|---|---|

| Databases | Article database (up to 30,000), Transaction memory (up to 300,000 entries), DatabICS PC software to manage database |

| Display | Graphical display (ICS4_5/685), colorWeight® (ICS465/685), |

| Housing | Robust die-cast aluminum, up to IP65 |

| Dimensions | XS, SM: 247x364x95-105 mm, LA: 357x404x110-120 mm |

| Platform size | XS: 160×130 mm, SM: 240×200 mm, LA: 350×240 mm |

| Interfaces | RS232, RS422/485, USB host/device, Ethernet, WLAN, Digital I/O |

| Platforms | Up to 3 additional weighing platforms attachable, SICSpro or analog |

| brands | Mettler Toledo |

| color | cream, White |

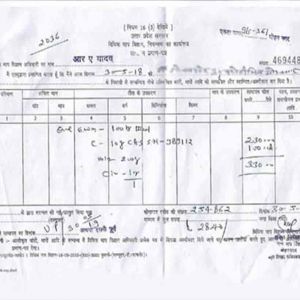

| Calibration Certificate | One Year Legal Metrology Department Calibration Certificate and Government Stamping |

| free delivery & Installation | Noida, Greater Noida, Ghaziabad & Delhi NCR |

| Counting Weighing Scale | |||

|---|---|---|---|

| Capacity | Readability | Minimum Reference Weight |

Minimum Average Piece Weight |

| 0.6 kg | 0.001 g | 0.05 g | 0.005 g |

| 0.12/0.6 kg | 0.001/0.01 g | 0.05 g | 0.005 g |

| 3 kg | 0.01 g | 0.5 g | 0.05 g |

| 0.6/3 kg | 0.01/0.1 g | 0.5 g | 0.05 g |

| 6 kg | 0.01 g | 0.5 g | 0.05 g |

| 1.2/6 kg | 0.01/0.1 g | 0.5 g | 0.05 g |

| 6 kg | 0.1 g | 0.5 g | 0.05 g |

| 1.2/6 kg | 0.1/1 g | 0.5 g | 0.05 g |

| 3 kg | 0.5 g | 2.5 g | 0.25 g |

| 6 kg | 1 g | 5 g | 0.5 g |

| 15 kg | 0.1 g | 5 g | 0.5 g |

| 3/15 kg | 0.1/1 g | 5 g | 0.5 g |

| 35 kg | 0.1 g | 5.8 g | 0.58 g |

| 7/35 kg | 0.1/1 g | 5.8 g | 0.58 g |

| 15 kg | 2 g | 12.5 g | 1.25 g |

| 35 kg | 5 g | 30 g | 3 g |

Based on 3 reviews

Add a review Cancel reply

You may also like…

-

Analytical Weighing Balance, Calibration Certificate, Calibration Weight, Cas Weighing Scale, Cast Iron Weight, Computer Interface Weighing Scale, Counting Weighing Scale, Electronic Weighing Machine, Essae Crane Scale, Essae Weighing Scale, Industrial Weighing Scale, Jewellery Scale, Label Printing Scale, Laboratory Scale, Legal Metrology Department, mettler toledo jewellery scales, Minebea Intec, OHAUS Weighing Balance, Pharmacy weighing scale, Piece Counting Weighing Scale, Price Computing Scale, Sansui Jewellery Scale, Testing Weight, UP Scales, Weighing Machine, Weighing Machine For Shops, Weighing Machine With Printer, weighing scale, Weighing Scale Accessories, Weight Indicator

Calibration Certificate for Weighing Scales

Analytical Weighing Balance, Calibration Certificate, Calibration Weight, Cas Weighing Scale, Cast Iron Weight, Computer Interface Weighing Scale, Counting Weighing Scale, Electronic Weighing Machine, Essae Crane Scale, Essae Weighing Scale, Industrial Weighing Scale, Jewellery Scale, Label Printing Scale, Laboratory Scale, Legal Metrology Department, mettler toledo jewellery scales, Minebea Intec, OHAUS Weighing Balance, Pharmacy weighing scale, Piece Counting Weighing Scale, Price Computing Scale, Sansui Jewellery Scale, Testing Weight, UP Scales, Weighing Machine, Weighing Machine For Shops, Weighing Machine With Printer, weighing scale, Weighing Scale Accessories, Weight IndicatorCalibration Certificate for Weighing Scales

Rated 5.00 out of 5(3)UP Scales is Official of Weight & Measurement Department and Legal Metrology Department for Providing Calibration Certificate, Government stamping & Passing to any weighing instruments. If you are looking for a Calibration Certificate, Government Stamping & Passing for your Weighing Scale/Machine you can call us on 9899008683.

[caldera_form id=”CF5cbeab187482a”]

SKU: calibration-certificate-for-weighing-scales -

Electronic Weighing Machine, Industrial Weighing Scale, Minebea Intec, Platform Weighing Scale, Weighing Machine, Weighing Machine For Shops, weighing scale

Industrial Weighing Scale 300 kg – Minebea Intec

Electronic Weighing Machine, Industrial Weighing Scale, Minebea Intec, Platform Weighing Scale, Weighing Machine, Weighing Machine For Shops, weighing scaleIndustrial Weighing Scale 300 kg – Minebea Intec

Rated 5.00 out of 5(3)Industrial weighing scale 300 kg offers a variety of solutions for a raft of Industrial Requirements and Applications and the Readability of the Industrial weighing scale 300 kg is 20 gm with a Calibration Certificate, Government stamping & Passing. Same-day free delivery in Noida, Greater Noida & Ghaziabad. Our all weighing scales are approved by the Weight & Measure department and Legal metrology department for use in Commercial and Personal use.

Get Free Delivery & Installation of all Weighing Scale in Only Delhi NCR – Noida, Greater Noida, Ghaziabad, Delhi, Gurugram, and Meerut (Note* – UP Scales don’t provide delivery & installation in outer Delhi NCR).

[caldera_form id=”CF5cbeab187482a”]

SKU: industrial-weighing-scale-300-kg-minebea-intec -

Electronic Weighing Machine, Industrial Weighing Scale, Minebea Intec, Platform Weighing Scale, Weighing Machine, Weighing Machine For Shops, weighing scale

Industrial Weighing Scale 150 kg – Minebea Intec

Electronic Weighing Machine, Industrial Weighing Scale, Minebea Intec, Platform Weighing Scale, Weighing Machine, Weighing Machine For Shops, weighing scaleIndustrial Weighing Scale 150 kg – Minebea Intec

Rated 5.00 out of 5(3)Industrial weighing scale 150 kg offers a variety of solutions for a raft of Industrial Requirements and Applications and the Readability of the Industrial weighing scale 150 kg is 10 gm with a Calibration Certificate, Government stamping & Passing. Same-day free delivery in Noida, Greater Noida & Ghaziabad. Our all weighing scales are approved by the Weight & Measure department and Legal metrology department for use in Commercial and Personal use.

[caldera_form id=”CF5cbeab187482a”]

SKU: industrial-weighing-scale-150-kg-minebea-intec -

Counting Weighing Scale, Electronic Weighing Machine, Jewellery Scale, Laboratory Scale, Price Computing Scale, UP Scales, Weighing Machine, Weighing Machine For Shops, weighing scale

Jewellery Scale Capacity – 200 gm to 2 kg Class 2nd | UP Scales

Counting Weighing Scale, Electronic Weighing Machine, Jewellery Scale, Laboratory Scale, Price Computing Scale, UP Scales, Weighing Machine, Weighing Machine For Shops, weighing scaleJewellery Scale Capacity – 200 gm to 2 kg Class 2nd | UP Scales

Rated 5.00 out of 5(4)This Jewellery scale is specially designed by UP Scales which have some rich features and first, of its own kind this jewellery scale has 4 weighing machine functions in one – Weighing, Computing, Counting & GSM measurement. This Jewellery scale is a complete solution to your all needs.

This Jewellery scale is approved by the legal metrology department for use in Commercial and Personal use. Same day delivery and Free Installation in Noida, Greater & Ghaziabad. For more information about the Jewellery scale, you can call us on 9899008683.

Get Free Delivery & Installation of all Weighing Scale in Only Delhi NCR – Noida, Greater Noida, Ghaziabad, Delhi, Gurugram, and Meerut (Note* – UP Scales don’t provide delivery & installation in outer Delhi NCR).

[caldera_form id=”CF5cbeab187482a”]

SKU: jewellery-scale-capacity-200-gm -

Commercial Weighing Scale, Computer Interface Weighing Scale, Counting Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, UP Scales, Weighing Machine, Weighing Machine For Shops, Weighing Machine With Printer, weighing scale

30 kg Steel Metal Weighing Scale – UP Scales

Commercial Weighing Scale, Computer Interface Weighing Scale, Counting Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, UP Scales, Weighing Machine, Weighing Machine For Shops, Weighing Machine With Printer, weighing scale30 kg Steel Metal Weighing Scale – UP Scales

Rated 5.00 out of 5(5)30 kg Steel Metal Weighing Scale body is equipped with a strong 16bit low power, high-speed Renesas microcontroller, and 24-bit sigma-delta ADC and provides an accuracy of 1gm at 30 kg Capacity. 30 Kg of steel metal weighing scale has two sets of displays on steel metal weighing scale one for the customer and one for Retailer.

30 kg Steel Metal Weighing Scale with Calibration Certificate and Government Stamping/Passing approved by Legal Metrology Department and Weight & Measurement Department for use in commercial and personal use. For more information or Booking Call us on 9899008683.

Get Free Delivery & Installation of all Weighing Scale in Only Delhi NCR – Noida, Greater Noida, Ghaziabad, Delhi, Gurugram, and Meerut (Note* – UP Scales don’t provide delivery & Installation in outer Delhi NCR).

[caldera_form id=”CF5cbeab187482a”]

SKU: 30-kg-steel-metal-weighing-scale

Related products

-

Cas Weighing Scale, Commercial Weighing Scale, Crane Scale, Electronic Weighing Machine, Hanging Scale, Industrial Weighing Scale, UP Scales, Weighing Machine, weighing scale

CAS Crane Scale

Cas Weighing Scale, Commercial Weighing Scale, Crane Scale, Electronic Weighing Machine, Hanging Scale, Industrial Weighing Scale, UP Scales, Weighing Machine, weighing scaleCAS Crane Scale

Rated 5.00 out of 5(3)CAS Digital Crane Scale with Calibration Certificate & Government Stamping from Weight & Measurement Department. Two Year Warranty & One Day Free Delivery in Noida, Greater Noida & Ghaziabad. Our all Weighing Machine is Government Approved for use in Commercial & Personal Use. For Weighing Machine(Booking) Call 9899008683.

Get Free Delivery & Installation of all Weighing Scale in Only Delhi NCR – Noida, Greater Noida, Ghaziabad, Delhi, Gurugram, and Meerut (Note* – UP Scales don’t provide delivery & installation in outer Delhi NCR).

SKU: cas-crane-scale -

Counting Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, Label Printing Scale, Platform Weighing Scale, Price Computing Scale, UP Scales, Weighing Machine, Weighing Machine For Shops, weighing scale

Platform Weighing Scale Capacity 500 kg – UP Scales

Counting Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, Label Printing Scale, Platform Weighing Scale, Price Computing Scale, UP Scales, Weighing Machine, Weighing Machine For Shops, weighing scalePlatform Weighing Scale Capacity 500 kg – UP Scales

Rated 4.60 out of 5(5)Platform weighing scale 500 kg capacity is specially designed for Industries & Shops. This platform scale is manufactured by UP Scales and gives complete assurance of the durability of Platform weighing scale and UP Scales manufactured this scale in two different body designs, first come in Complete metal body and second variant in Stainless steel body. This platform weighing scale of 500 kg is one of its own kind this platform scale has three weighing scale features in one – Weighing, Counting, Computing & litre Conversion.

Our platform weighing scale 500 kg is approved by the legal metrology department and Weight & Measurement department for use in Commercial and Personal Use. For more information or booking about Platform weighing scale 500 kg, you can also call us on 9899008683.

[caldera_form id=”CF5cbeab187482a”]

SKU: platform-weighing-scale-capacity-500kg -

Analytical Weighing Balance, Commercial Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, Jewellery Scale, Laboratory Scale, OHAUS Weighing Balance, Pharmacy weighing scale, UP Scales, Weighing Machine, weighing scale

Weighing Scale for Pharmacy – OHAUS

Analytical Weighing Balance, Commercial Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, Jewellery Scale, Laboratory Scale, OHAUS Weighing Balance, Pharmacy weighing scale, UP Scales, Weighing Machine, weighing scaleWeighing Scale for Pharmacy – OHAUS

Rated 5.00 out of 5(3)Weighing Scale for Pharmacy with Capacity of 52 gm and readability 0.00001 gm with Calibration Certificate & Government Stamping from Weight & Measurement Department. Offering accuracy and repeatability for essential pharmacy weighing applications, Weighing Scale for Pharmacy – OHAUS delivers competitive performance.

Get Free Delivery & Installation of all Weighing Scale in Only Delhi NCR – Noida, Greater Noida, Ghaziabad, Delhi, Gurugram, and Meerut (Note* – UP Scales don’t provide delivery & installation in outer Delhi NCR).

[caldera_form id=”CF5cbeab187482a”]One Year Warranty & One Day Free Delivery in Noida, Greater Noida & Ghaziabad. Our all Weighing Machine is Government Approved for use in Commercial & Personal Use. For Weighing Machine(Booking) Call 9899008683

SKU: weighing-scale-for-pharmacy-ohaus -

Cas Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, Platform Weighing Scale, UP Scales, Weighing Machine, weighing scale, Weighing Scale Accessories, Weight Indicator

Weighing Scale Indicator – CAS

Cas Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, Platform Weighing Scale, UP Scales, Weighing Machine, weighing scale, Weighing Scale Accessories, Weight IndicatorWeighing Scale Indicator – CAS

Rated 5.00 out of 5(3)Weighing Scale Indicator – CAS, Connectable with various sizes of weighing platform scales for versatile applications such as open markets and retail stores. For Booking Call us on 9899008683, Our all weighing scales are Government approved for Use in Commercial and Personal use.

Get Free Delivery & Installation of all Weighing Scale in Only Delhi NCR – Noida, Greater Noida, Ghaziabad, Delhi, Gurugram, and Meerut (Note* – UP Scales don’t provide delivery & installation in outer Delhi NCR).

SKU: weighing-scale-indicator-cas -

Commercial Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, Platform Weighing Scale, UP Scales, Weighing Machine, weighing scale

Heavy Duty Platform Weighing Scale 1 Ton | Platform Size (800X800 mm), (900X900 mm), (1000×1000 mm), (1200×1200 mm)

Commercial Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, Platform Weighing Scale, UP Scales, Weighing Machine, weighing scaleHeavy Duty Platform Weighing Scale 1 Ton | Platform Size (800X800 mm), (900X900 mm), (1000×1000 mm), (1200×1200 mm)

Rated 5.00 out of 5(3)Heavy Duty Platform Weighing Scale 1 ton with Calibration Certificate & Government Stamping from Weight & Measurement Department. One Year Warranty & One Day Free Delivery in Noida, Greater Noida & Ghaziabad. Our all Weighing Machine is Government Approved for use in Commercial & Personal Use. For Weighing Machine(Booking) Call 9899008683.

Get Free Delivery & Installation of all Weighing Scale in Only Delhi NCR – Noida, Greater Noida, Ghaziabad, Delhi, Gurugram, and Meerut (Note* – UP Scales don’t provide delivery & installation in outer Delhi NCR).

SKU: heavy-duty-platform-weighing-scale-1ton -

Analytical Weighing Balance, Commercial Weighing Scale, Computer Interface Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, Jewellery Scale, Laboratory Scale, Pharmacy weighing scale, Sansui Jewellery Scale, Sartorius Weighing Balance, Weighing Machine, weighing scale

Sartorius High-Capacity Micro and Semi-Micro Balances | Capacity 31 gm and Readability 0.001 mg

Analytical Weighing Balance, Commercial Weighing Scale, Computer Interface Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, Jewellery Scale, Laboratory Scale, Pharmacy weighing scale, Sansui Jewellery Scale, Sartorius Weighing Balance, Weighing Machine, weighing scaleSartorius High-Capacity Micro and Semi-Micro Balances | Capacity 31 gm and Readability 0.001 mg

Rated 5.00 out of 5(3)Sartorius High-Capacity Micro and Semi-Micro Balances of Capacity 31 gm and Readability 0.001 mg with Government calibration and verification certificate.

Sartorius offers a wide selection of ultramicro, micro, analytical, and precision balances that allow you to choose any entry-level to high-performance balance.

With more than 140 years of experience and quality “Made in Germany,” Sartorius offers the best weighing option by excelling in speed, repeatability, and accuracy. They feature a monolithic weigh cell – a technology that we first introduced and that continues at the leading edge in lab weighing.

[caldera_form id=”CF5cbeab187482a”]

SKU: sartorius-high-capacity-laboratory-balance -

Counting Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, Piece Counting Weighing Scale, Platform Weighing Scale, UP Scales, Weighing Machine, weighing scale

Bench and Floor Counting Scales | Capacity upto 60 kg | UP Scales

Counting Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, Piece Counting Weighing Scale, Platform Weighing Scale, UP Scales, Weighing Machine, weighing scaleBench and Floor Counting Scales | Capacity upto 60 kg | UP Scales

Rated 5.00 out of 5(3)Floor counting scales offer a removable, easy-to-clean stainless steel platform, providing an excellent value for industrial counting tasks. Store and recall up to 1006 PLUs or piece weights to improve efficiency in production or warehouse applications. The Floor counting scale features a built-in printer that prints weight, QR codes, bar codes, and labels, which can be customized using the included software. Choose from two platform sizes to meet the demands of inventory tasks, batching, shipping, and receiving. RS-232 interface provides a speedy connection to computers and printers.

Get Free Delivery & Installation of all Weighing Scale in Only Delhi NCR – Noida, Greater Noida, Ghaziabad, Delhi, Gurugram, and Meerut (Note* – UP Scales don’t provide delivery & installation in outer Delhi NCR).

SKU: bench-and-floor-counting-scales -

Cas Weighing Scale, Commercial Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, Platform Weighing Scale, UP Scales, Weighing Machine, weighing scale

Industrial Weighing Scale 600 kg Capacity – CAS

Cas Weighing Scale, Commercial Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, Platform Weighing Scale, UP Scales, Weighing Machine, weighing scaleIndustrial Weighing Scale 600 kg Capacity – CAS

Rated 5.00 out of 5(3)Industrial Platform Weighing Scale – CAS Capacity 600kg with Government passing & Stamping and with various variable platform size 300x300mm, 400x400mm, 500x500mm with Readability of 0.100gm. Industrial Platform weighing scale 100kg with Calibration certificate, for Booking call us on 9899008683. Our all weighing machine is Government approved for use in Commercial and Personal use.

Get Free Delivery & Installation of all Weighing Scale in Only Delhi NCR – Noida, Greater Noida, Ghaziabad, Delhi, Gurugram, and Meerut (Note* – UP Scales don’t provide delivery & installation in outer Delhi NCR).

[caldera_form id=”CF5cbeab187482a”]

SKU: industrial-weighing-scale-600kg-capacity-cas -

Counting Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, Laboratory Scale, Piece Counting Weighing Scale, Platform Weighing Scale, UP Scales, Weighing Machine, Weighing Machine For Shops, weighing scale

Weighing Machine Noida | Electronic Weighing Scale Noida

Counting Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, Laboratory Scale, Piece Counting Weighing Scale, Platform Weighing Scale, UP Scales, Weighing Machine, Weighing Machine For Shops, weighing scaleWeighing Machine Noida | Electronic Weighing Scale Noida

Rated 4.67 out of 5(3)The Weighing Machine Noida can be supplied as a Class III, EC, and OIML trade approved bench-scale system at 3,000 divisions as well as 6,000 divisions for applications where trade approval is not required. As a system, the Weighing Machine Noida Base combines with a pole-mounted indicator that can be used for a wide range of general-purpose floor or bench base type applications.

Capacity from 50 gm to 5 tons. Get free delivery & Installation in Noida. For Booking or more information you can Whatsapp or call us on 9899008683.

[caldera_form id=”CF5cbeab187482a”]

SKU: weighing-machine-noida -

Commercial Weighing Scale, Computer Interface Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, OHAUS Weighing Balance, Platform Weighing Scale, UP Scales, Weighing Machine, Weighing Machine For Shops, weighing scale

OHAUS Industrial Weighing Scale | Capacity 10 kg, 20 kg, 80 kg

Commercial Weighing Scale, Computer Interface Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, OHAUS Weighing Balance, Platform Weighing Scale, UP Scales, Weighing Machine, Weighing Machine For Shops, weighing scaleOHAUS Industrial Weighing Scale | Capacity 10 kg, 20 kg, 80 kg

Rated 5.00 out of 5(3)OHAUS Industrial Weighing scale or Bench Scale with Capacity of 9kg, 20kg & 75kg and readability of 0.01gm, 0.02 gm & 0.1 gm with Calibration Certificate & Government Stamping from Weight & Measurement Department. OHAUS Industrial Weighing scale compact bench scales are the perfect solution for home use, general shipping applications, veterinary weighing, and other dry weighing applications where low cost, portability, and precision are required.

Get Free Delivery & Installation of all Weighing Scale in Only Delhi NCR – Noida, Greater Noida, Ghaziabad, Delhi, Gurugram, and Meerut (Note* – UP Scales don’t provide delivery & installation in outer Delhi NCR).

[caldera_form id=”CF5cbeab187482a”]

One Year Warranty & One Day Free Delivery in Noida, Greater Noida & Ghaziabad. Our all Weighing Machine is Government Approved for use in Commercial & Personal Use. For Weighing Machine(Booking) Call 9899008683SKU: ohaus-industrial-weighing-scale -

Cas Weighing Scale, Commercial Weighing Scale, Computer Interface Weighing Scale, Counting Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, Piece Counting Weighing Scale, Price Computing Scale, Weighing Machine, Weighing Machine For Shops, weighing scale

Digital Weighing Scale 30 kg – CAS

Cas Weighing Scale, Commercial Weighing Scale, Computer Interface Weighing Scale, Counting Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, Piece Counting Weighing Scale, Price Computing Scale, Weighing Machine, Weighing Machine For Shops, weighing scaleDigital Weighing Scale 30 kg – CAS

Rated 5.00 out of 5(3)Cas Digital Weighing Scale 30 kg with Calibration Certificate & Government Stamping from Weight & Measurement Department. Two Year Warranty & One Day Free Delivery in Noida, Greater Noida & Ghaziabad. Our all Weighing Machine is Government Approved for use in Commercial & Personal Use. For Weighing Machine(Booking) Call 9899008683.

Get Free Delivery & Installation of all Weighing Scale in Only Delhi NCR – Noida, Greater Noida, Ghaziabad, Delhi, Gurugram, and Meerut (Note* – UP Scales don’t provide delivery & installation in outer Delhi NCR).

SKU: cas-digital-weighing-scale-30-kg -

Commercial Weighing Scale, Computer Interface Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, UP Scales, Weighing Machine, Weighing Machine For Shops, Weighing Machine With Printer, weighing scale

Electronic Weighing Machine 5 kg | Readability 200 mg | Goverment Approved

Commercial Weighing Scale, Computer Interface Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, UP Scales, Weighing Machine, Weighing Machine For Shops, Weighing Machine With Printer, weighing scaleElectronic Weighing Machine 5 kg | Readability 200 mg | Goverment Approved

Rated 5.00 out of 5(3)UP Scales manufacture made in India electronic weighing machine for shops and Industrial use, electronic weighing machine capacity 5 kg and e value 200 mg with heavy-duty structure and platform size of 175×225 mm, 170×210 mm, 240 x 300 mm. Our all electronic weighing scale is approved by Legal Metrology Department (Weight & Measurement Department) and OIML to use in Commerical, Industrial, and Personal use, our electronic weighing machine also comes with Government calibration verification certificate and stamping.

Get Free Delivery & Installation of all Weighing Scale in Only Delhi NCR – Noida, Greater Noida, Ghaziabad, Delhi, Gurugram, and Meerut (Note* – UP Scales don’t provide delivery in outer Delhi NCR).

[caldera_form id=”CF5cbeab187482a”]

SKU: electronic-weighing-machine-5-kg-200-mg -

Commercial Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, UP Scales, Weighing Machine, Weighing Machine For Shops, weighing scale

Electronic Weighing Machine for Shop 20 kg

Commercial Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, UP Scales, Weighing Machine, Weighing Machine For Shops, weighing scaleElectronic Weighing Machine for Shop 20 kg

Rated 5.00 out of 5(3)Weighing Machine/Scales for Shops 20kg with Calibration Certificate & Government Stamping from Weight & Measurement Department. One Year Warranty & One Day Free Delivery in Noida, Greater Noida & Ghaziabad. Our all Weighing Machine is Government Approved for use in Commercial & Personal Use. For Weighing Machine(Booking) Call 9899008683.

Get Free Delivery & Installation of all Weighing Scale in Only Delhi NCR – Noida, Greater Noida, Ghaziabad, Delhi, Gurugram, and Meerut (Note* – UP Scales don’t provide delivery & installation in outer Delhi NCR).

SKU: electronic-weighing-machine-for-shop-20kg -

Commercial Weighing Scale, Computer Interface Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, UP Scales, Weighing Machine, Weighing Machine For Shops, Weighing Machine With Printer, weighing scale

Electronic Weighing Machine 10 kg | Readability 500 mg | Goverment Approved

Commercial Weighing Scale, Computer Interface Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, UP Scales, Weighing Machine, Weighing Machine For Shops, Weighing Machine With Printer, weighing scaleElectronic Weighing Machine 10 kg | Readability 500 mg | Goverment Approved

Rated 5.00 out of 5(3)UP Scales manufacture made in India electronic weighing machine for shops and Industrial use, electronic weighing machine capacity 10 kg and e value 500 mg with heavy-duty structure and platform size of 175×225 mm, 170×210 mm, 240 x 300 mm. Our all electronic weighing scale is approved by Legal Metrology Department (Weight & Measurement Department) and OIML to use in Commerical, Industrial, and Personal use, our electronic weighing machine also comes with Government calibration verification certificate and stamping.

Get Free Delivery & Installation of all Weighing Scale in Only Delhi NCR – Noida, Greater Noida, Ghaziabad, Delhi, Gurugram, and Meerut (Note* – UP Scales don’t provide delivery in outer Delhi NCR).

[caldera_form id=”CF5cbeab187482a”]

SKU: electronic-weighing-machine-10-kg-500-mg -

Crane Scale, Electronic Weighing Machine, Hanging Scale, Industrial Weighing Scale, UP Scales, Waterproof Weighing Scale, Weighing Machine, weighing scale

Crane Scale 1 ton, 2 ton, 3 ton, 5 ton | OCS Crane Scale & Hanging Scale | UP Scales

Crane Scale, Electronic Weighing Machine, Hanging Scale, Industrial Weighing Scale, UP Scales, Waterproof Weighing Scale, Weighing Machine, weighing scaleCrane Scale 1 ton, 2 ton, 3 ton, 5 ton | OCS Crane Scale & Hanging Scale | UP Scales

Rated 5.00 out of 5(3)Electronic Crane scale with capacity 1 ton, 2 ton, 3 ton & 5 ton with Government calibration verification certificate and Stamping. This electronic weighing scale has a wireless remote control with a distance of more than 1 Km.

Get Free Delivery & Installation of all Weighing Scale in Only Delhi NCR – Noida, Greater Noida, Ghaziabad, Delhi, Gurugram, and Meerut (Note* – UP Scales don’t provide delivery in outer Delhi NCR).

[caldera_form id=”CF5cbeab187482a”]

SKU: crane-scale-ocs -

Cas Weighing Scale, Crane Scale, Electronic Weighing Machine, Essae Crane Scale, Hanging Scale, Industrial Weighing Scale, OHAUS Weighing Balance, UP Scales, Weighing Machine, weighing scale

Crane Scale | Capacity 500 kg | Aluminium Electronic Crane Suspension Scale

Cas Weighing Scale, Crane Scale, Electronic Weighing Machine, Essae Crane Scale, Hanging Scale, Industrial Weighing Scale, OHAUS Weighing Balance, UP Scales, Weighing Machine, weighing scaleCrane Scale | Capacity 500 kg | Aluminium Electronic Crane Suspension Scale

Rated 4.50 out of 5(8)Crane scales are ideal for weighing goods to ensure vehicles or cranes are not overloaded. Constructed from aluminum the crane scale hard-wearing, reliable and built to last. It has a choice of capacities and can be operated from a distance. Lightweight aluminum crane scale capacity 500 kg with Infra-red remote control for safe and easy operation and Bright red LED clearly visible weight display with Government approved Calibration certificate and Stamping.

Crane Scale is approved by the legal metrology department and Weight & Measurement department for use in Commercial and Personal use. for more information about the crane scale, you can also call us on 9899008683.

Get Free Delivery & Installation of all Weighing Scale in Only Delhi NCR – Noida, Greater Noida, Ghaziabad, Delhi, Gurugram, and Meerut (Note* – UP Scales don’t provide delivery & installation in outer Delhi NCR).

[caldera_form id=”CF5cbeab187482a”]

SKU: crane-scale-capacity-500-kg -

Commercial Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, UP Scales, Waterproof Weighing Scale, Weighing Machine, Weighing Machine For Shops, Weighing Machine With Printer, weighing scale

Weighing Machine For Shop 30 kg | e value 1 gm, 2 gm, 5 gm | Platform Size 250×300 mm

Commercial Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, UP Scales, Waterproof Weighing Scale, Weighing Machine, Weighing Machine For Shops, Weighing Machine With Printer, weighing scaleWeighing Machine For Shop 30 kg | e value 1 gm, 2 gm, 5 gm | Platform Size 250×300 mm

Rated 5.00 out of 5(3)UP Scales is the biggest Indian manufacturer of weighing machines for shops, our weighing machine for shop 30 kg also comes in various variants like 5 kg, 10 kg, 20 kg and 40 kg also with Government calibration verification certificate and stamping.

Get Free same day Delivery & Installation in Noida, Greater Noida, Ghaziabad, Delhi, and Complete Delhi NCR with Government Calibration Verification Certificate and Stamping.

[caldera_form id=”CF5cbeab187482a”]

SKU: weighing-machine-for-shop-2 -

Counting Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, Piece Counting Weighing Scale, Platform Weighing Scale, UP Scales, Weighing Machine, Weighing Machine For Shops, weighing scale

Bench Counting Scale | Platform Counting Scale | Capacity upto 60 kg

Counting Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, Piece Counting Weighing Scale, Platform Weighing Scale, UP Scales, Weighing Machine, Weighing Machine For Shops, weighing scaleBench Counting Scale | Platform Counting Scale | Capacity upto 60 kg

Rated 5.00 out of 5(3)The Bench Counting Scale is a fully featured counting scale with a numeric keypad for unit weight and sample entry. The large, brightly backlit display shows unit weight, total weight, and a number of pieces. With a grade 304 stainless steel pan and pillar-mounted ABS plastic indicator, the Bench Counting Scale provides a durable, reliable solution for industrial counting tasks. Power is supplied by a mains power cord or the built-in, rechargeable battery.

Get Free Delivery & Installation of all Weighing Scale in Only Delhi NCR – Noida, Greater Noida, Ghaziabad, Delhi, Gurugram, and Meerut (Note* – UP Scales don’t provide delivery & installation in outer Delhi NCR).

[caldera_form id=”CF5cbeab187482a”]

SKU: bench-counting-scale -

Cas Weighing Scale, Commercial Weighing Scale, Computer Interface Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, Label Printing Scale, Price Computing Scale, Weighing Machine, Weighing Machine For Shops, weighing scale

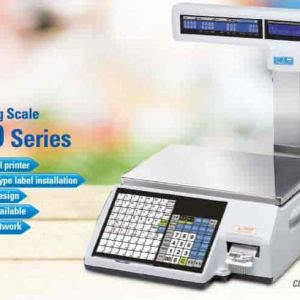

Label Printing Scale – CAS | Price Computing Weighing Machine

Cas Weighing Scale, Commercial Weighing Scale, Computer Interface Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, Label Printing Scale, Price Computing Scale, Weighing Machine, Weighing Machine For Shops, weighing scaleLabel Printing Scale – CAS | Price Computing Weighing Machine

Rated 5.00 out of 5(3)Cas Digital Weighing Scale CL7200 Series with Dual-color LCD display with Calibration Certificate & Government Stamping from Weight & Measurement Department. Two Year Warranty & One Day Free Delivery in Noida, Greater Noida & Ghaziabad. Our all Weighing Machine is Government Approved for use in Commercial & Personal Use. For Weighing Machine(Booking) Call 9899008683.

Get Free Delivery & Installation of all Weighing Scale in Only Delhi NCR – Noida, Greater Noida, Ghaziabad, Delhi, Gurugram, and Meerut (Note* – UP Scales don’t provide delivery & installation in outer Delhi NCR).

SKU: cas-label-printing-scale-cl7200-series -

Cas Weighing Scale, Crane Scale, Electronic Weighing Machine, Essae Crane Scale, Hanging Scale, Industrial Weighing Scale, UP Scales, Weighing Machine, weighing scale

Crane Scale | Capacity 5 Ton | Aluminium Electronic Crane Suspension Scale

Cas Weighing Scale, Crane Scale, Electronic Weighing Machine, Essae Crane Scale, Hanging Scale, Industrial Weighing Scale, UP Scales, Weighing Machine, weighing scaleCrane Scale | Capacity 5 Ton | Aluminium Electronic Crane Suspension Scale

Rated 5.00 out of 5(4)Crane scales are ideal for weighing goods to ensure vehicles or cranes are not overloaded. Constructed from aluminum the crane scale hard-wearing, reliable, and built to last. It has a choice of capacities and can be operated from a distance. Lightweight aluminum crane scale capacity 5-ton with Infra-red remote control for safe and easy operation and Bright red LED clearly visible weight display with Government approved Calibration certificate and Stamping.

Crane Scale is approved by the legal metrology department and Weight & Measurement department for use in Commercial and Personal use. for more information about the crane scale, you can also call us on 9899008683.

Get Free Delivery & Installation of all Weighing Scale in Only Delhi NCR – Noida, Greater Noida, Ghaziabad, Delhi, Gurugram, and Meerut (Note* – UP Scales don’t provide delivery & installation in outer Delhi NCR).

[caldera_form id=”CF5cbeab187482a”]

SKU: crane-scale-capacity-5-ton -

Commercial Weighing Scale, Computer Interface Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, Platform Weighing Scale, UP Scales, Weighing Machine, Weighing Machine For Shops, Weighing Machine With Printer, weighing scale

Industrial Weighing Scale | Capacity 50 kg, e value 5 gm | Platform Size 350×350 mm

Commercial Weighing Scale, Computer Interface Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, Platform Weighing Scale, UP Scales, Weighing Machine, Weighing Machine For Shops, Weighing Machine With Printer, weighing scaleIndustrial Weighing Scale | Capacity 50 kg, e value 5 gm | Platform Size 350×350 mm

Rated 5.00 out of 5(3)UP Scales manufacture made in India industrial weighing scale for shops and Industrial use, Industrial weighing scale capacity 50 kg and e value 5 gm with heavy-duty structure and platform size of 350×350 mm. Our all industrial weighing scale is approved by Legal Metrology Department (Weight & Measurement Department) and OIML to use in Commerical, Industrial, and Personal use, our industrial weighing scale also comes with a Government calibration verification certificate and stamping.

Get Free Delivery & Installation of all Weighing Scale in Only Delhi NCR – Noida, Greater Noida, Ghaziabad, Delhi, Gurugram, and Meerut (Note* – UP Scales don’t provide delivery in outer Delhi NCR).

[caldera_form id=”CF5cbeab187482a”]

SKU: industrial-weighing-scale-capacity-50-kg-5-gm -

Analytical Weighing Balance, Electronic Weighing Machine, Jewellery Scale, Laboratory Scale, OHAUS Weighing Balance, Pharmacy weighing scale, Weighing Machine, weighing scale

Analytical and Precision Weighing Balance | High Capacity Weighing Balance Scale | Capacity 100gm, 200gm, 300gm, 400gm, 600gm, 1kg, 2kg 3kg

Analytical Weighing Balance, Electronic Weighing Machine, Jewellery Scale, Laboratory Scale, OHAUS Weighing Balance, Pharmacy weighing scale, Weighing Machine, weighing scaleAnalytical and Precision Weighing Balance | High Capacity Weighing Balance Scale | Capacity 100gm, 200gm, 300gm, 400gm, 600gm, 1kg, 2kg 3kg

Rated 4.67 out of 5(3)The Analytical and Precision weighing balance has risen to the next level of ingenuity—expanding on its modern features & design to offer unmatched functionality in a line of high-performance balances unlike any other on the market.

The Capacity of analytical and precision weighing balance is 50 gm, 100 gm, 200 gm, 300 gm, 400 gm, 500 gm, 600 gm, 1 kg, 2 kg, 3 kg, 5 kg, 6 kg and 11 kg and readability 0.1 mg, 0.01 mg and 0.001 mg

Our analytical and Precision weighing balance is approved by Legal Metrology Department and weight & Measurement department for use in commercial and personal use. for more information or booking related concern you can call us on 9899008683.

Get Free Delivery & Installation of all Weighing Scale in Only Delhi NCR – Noida, Greater Noida, Ghaziabad, Delhi, Gurugram, and Meerut (Note* – UP Scales don’t provide delivery & installation in outer Delhi NCR).

[caldera_form id=”CF5cbeab187482a”]

SKU: analytical-and-precision-weighing-balance -

Commercial Weighing Scale, Computer Interface Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, Platform Weighing Scale, UP Scales, Weighing Machine, Weighing Machine For Shops, Weighing Machine With Printer, weighing scale

Industrial Weighing Scale | Capacity 500 kg, e value 50 gm | Platform Size 600×600 mm

Commercial Weighing Scale, Computer Interface Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, Platform Weighing Scale, UP Scales, Weighing Machine, Weighing Machine For Shops, Weighing Machine With Printer, weighing scaleIndustrial Weighing Scale | Capacity 500 kg, e value 50 gm | Platform Size 600×600 mm

Rated 5.00 out of 5(3)UP Scales manufacture made in India industrial weighing scale for shops and Industrial use, Industrial weighing scale capacity 5o0 kg and e value 50 gm with heavy-duty structure and platform size of 600×600 mm, 750×750 mm. Our all industrial weighing scale is approved by Legal Metrology Department (Weight & Measurement Department) and OIML to use in Commerical, Industrial, and Personal use, our industrial weighing scale also comes with a Government calibration verification certificate and stamping.

Get Free Delivery & Installation of all Weighing Scale in Only Delhi NCR – Noida, Greater Noida, Ghaziabad, Delhi, Gurugram, and Meerut (Note* – UP Scales don’t provide delivery in outer Delhi NCR).

[caldera_form id=”CF5cbeab187482a”]

SKU: industrial-weighing-scale-capacity-500-kg-50-gm -

Commercial Weighing Scale, Computer Interface Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, Platform Weighing Scale, UP Scales, Weighing Machine, Weighing Machine For Shops, Weighing Machine With Printer, weighing scale

Industrial Weighing Scale | Capacity 2000 kg, e value 200 gm | Platform Size 1200×1200 mm

Commercial Weighing Scale, Computer Interface Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, Platform Weighing Scale, UP Scales, Weighing Machine, Weighing Machine For Shops, Weighing Machine With Printer, weighing scaleIndustrial Weighing Scale | Capacity 2000 kg, e value 200 gm | Platform Size 1200×1200 mm

Rated 5.00 out of 5(3)UP Scales manufacture made in India industrial weighing scale for shops and Industrial use, Industrial weighing scale capacity 2000 kg and e value 200 gm with heavy-duty structure and platform size of 1200×1200 mm, 1500x1500mm. Our all industrial weighing scale is approved by Legal Metrology Department (Weight & Measurement Department) and OIML to use in Commerical, Industrial, and Personal use, our industrial weighing scale also comes with a Government calibration verification certificate and stamping.

Get Free Delivery & Installation of all Weighing Scale in Only Delhi NCR – Noida, Greater Noida, Ghaziabad, Delhi, Gurugram, and Meerut (Note* – UP Scales don’t provide delivery in outer Delhi NCR).

[caldera_form id=”CF5cbeab187482a”]

SKU: industrial-weighing-scale-capacity-2000-kg-200-gm -

Cas Weighing Scale, Commercial Weighing Scale, Crane Scale, Electronic Weighing Machine, Hanging Scale, Industrial Weighing Scale, Laboratory Scale, UP Scales, Weighing Machine, weighing scale

Crane Scale | CAS IE – 1700 Series | Capacity 50 kg, 100 kg, 200 kg, 300 kg, 500 kg, 1000 kg

Cas Weighing Scale, Commercial Weighing Scale, Crane Scale, Electronic Weighing Machine, Hanging Scale, Industrial Weighing Scale, Laboratory Scale, UP Scales, Weighing Machine, weighing scaleCrane Scale | CAS IE – 1700 Series | Capacity 50 kg, 100 kg, 200 kg, 300 kg, 500 kg, 1000 kg

Rated 5.00 out of 5(3)IE 1700 series have high quality and heavy-duty product in a rough industrial environment. The product is operated according to OIML R76 and get the European CE certificate.

Capacity of CAS Crane Scale IE 1700 – 50 kg, 1000 kg, 200 kg, 300 kg, 500 kg & 1000 kg

Get Free Delivery & Installation of all Weighing Scale in Only Delhi NCR – Noida, Greater Noida, Ghaziabad, Delhi, Gurugram, and Meerut (Note* – UP Scales don’t provide delivery in outer Delhi NCR).

[caldera_form id=”CF5cbeab187482a”]

SKU: crane-scale-cas-ie-1700 -

Commercial Weighing Scale, Computer Interface Weighing Scale, Electronic Weighing Machine, Essae Weighing Scale, Industrial Weighing Scale, Platform Weighing Scale, UP Scales, Weighing Machine, Weighing Machine For Shops, Weighing Machine With Printer, weighing scale

Digital Weighing Scale | 50 kg to 200 kg Bench Scale | DS-415N Essae

Commercial Weighing Scale, Computer Interface Weighing Scale, Electronic Weighing Machine, Essae Weighing Scale, Industrial Weighing Scale, Platform Weighing Scale, UP Scales, Weighing Machine, Weighing Machine For Shops, Weighing Machine With Printer, weighing scaleDigital Weighing Scale | 50 kg to 200 kg Bench Scale | DS-415N Essae

Rated 5.00 out of 5(3)The 415N Bench type mount design structure features a unique Green VFD which is clearly visible whatever the light conditions or at a fair distance. Ideally suited for both retail & industrial environments, digital weighing scale capacity ranges from 50 kg to 2000 kg and e value 5/10/20/50 gm with heavy-duty structure and platform size of 420×550 mm, 505×550 mm, 600×600 mm. Our all-digital weighing scale is approved by Legal Metrology Department (Weight & Measurement Department) and OIML to use in Commerical, Industrial, and Personal use, our digital weighing scale also comes with a Government calibration verification certificate and stamping.

Get Free Delivery & Installation of all Weighing Scale in Only Delhi NCR – Noida, Greater Noida, Ghaziabad, Delhi, Gurugram, and Meerut (Note* – UP Scales don’t provide delivery in outer Delhi NCR).

[caldera_form id=”CF5cbeab187482a”]

SKU: digital-weighing-scale-50-kg-to-200-kg-ds-415n -

Analytical Weighing Balance, Electronic Weighing Machine, Industrial Weighing Scale, Laboratory Scale, Mettler Toledo, Pharmacy weighing scale, Weighing Machine, weighing scale

Analytical Balances | Capacity 120 gm Readability 0.01 mg & 0.1 mg | METTLER TOLEDO’s

Analytical Weighing Balance, Electronic Weighing Machine, Industrial Weighing Scale, Laboratory Scale, Mettler Toledo, Pharmacy weighing scale, Weighing Machine, weighing scaleAnalytical Balances | Capacity 120 gm Readability 0.01 mg & 0.1 mg | METTLER TOLEDO’s

Rated 5.00 out of 5(3)METTLER TOLEDO introduces a new dimension in analytical weighing with a combination of intelligent features to make your daily weighing tasks easy and error-free.

You not only benefit from the outstanding weighing performance of Excellence analytical balances but you can also be sure of full regulatory compliance and high process security.

- Easy Balance Management

- Electrostatic Solutions

- Full Process Control

Enjoy weighing with METTLER TOLEDO innovations.

[caldera_form id=”CF5cbeab187482a”]

SKU: analytical-balances-mettler-toledos -

Crane Scale, Electronic Weighing Machine, Essae Crane Scale, Hanging Scale, Industrial Weighing Scale, UP Scales, Weighing Machine, weighing scale

Crane Scale | Capacity 50kg, 100kg, 200kg, 300kg, 500kg, 1ton, 2ton, 5ton

Crane Scale, Electronic Weighing Machine, Essae Crane Scale, Hanging Scale, Industrial Weighing Scale, UP Scales, Weighing Machine, weighing scaleCrane Scale | Capacity 50kg, 100kg, 200kg, 300kg, 500kg, 1ton, 2ton, 5ton

Rated 5.00 out of 5(3)Crane Scale for Cranes or use it as Hanging 50kg, 100kg, 200kg, 300kg, 500kg, 1 ton, 2 ton, 5 ton with Calibration Certificate & Government Stamping from Weight & Measurement Department. One Year Warranty & One Day Free Delivery in Noida, Greater Noida & Ghaziabad. Our all Weighing Machine are Government Approved for use in Commercial & Personal Use. For Weighing Machine(Booking) Call 9899008683.

Get Free Delivery & Installation of all Weighing Scale in Only Delhi NCR – Noida, Greater Noida, Ghaziabad, Delhi, Gurugram, and Meerut (Note* – UP Scales don’t provide delivery & installation in outer Delhi NCR).

SKU: crane-scale -

Commercial Weighing Scale, Computer Interface Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, Platform Weighing Scale, UP Scales, Weighing Machine, weighing scale

Platform Weighing Scale 500 kg | Platform Size (500X500 mm), (600 X 600 mm), (700×700 mm), (1×1 m)

Commercial Weighing Scale, Computer Interface Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, Platform Weighing Scale, UP Scales, Weighing Machine, weighing scalePlatform Weighing Scale 500 kg | Platform Size (500X500 mm), (600 X 600 mm), (700×700 mm), (1×1 m)

Rated 5.00 out of 5(3)Platform Weighing Scale 500kg with Calibration Certificate & Government Stamping from Weight & Measurement Department. One Year Warranty & One Day Free Delivery in Noida, Greater Noida & Ghaziabad. Our all Weighing Machine is Government Approved for use in Commercial & Personal Use. For Weighing Machine(Booking) Call 9899008683.

Get Free Delivery & Installation of all Weighing Scale in Only Delhi NCR – Noida, Greater Noida, Ghaziabad, Delhi, Gurugram, and Meerut (Note* – UP Scales don’t provide delivery & installation in outer Delhi NCR).

SKU: platform-weighing-scale-500-kg -

Analytical Weighing Balance, Cas Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, Jewellery Scale, Laboratory Scale, UP Scales, Weighing Machine, weighing scale

High Performance Precision Balance – CAS | Micro Weighing Scale | Capacity 600 gm & Readability 0.02 gm

Analytical Weighing Balance, Cas Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, Jewellery Scale, Laboratory Scale, UP Scales, Weighing Machine, weighing scaleHigh Performance Precision Balance – CAS | Micro Weighing Scale | Capacity 600 gm & Readability 0.02 gm

Rated 4.67 out of 5(3)High-performance precision balance Micro-Weighing scale with superior performance measuring up to 150-6000 gm weight. The operating temperature is 5˚C – 40˚C. Therefore accurate measurement is possible in any workplace. Moreover, with its superior performance, various interfaces, and easy power charging, therefore efficient measure is possible. the High-performance precision balance Micro-Weighing scale will be taking on a new standard of Micro-Weighing Scale.

Get Free Delivery & Installation of all Weighing Scale in Only Delhi NCR – Noida, Greater Noida, Ghaziabad, Delhi, Gurugram, and Meerut (Note* – UP Scales don’t provide delivery & installation in outer Delhi NCR).

[caldera_form id=”CF5cbeab187482a”]

SKU: high-performance-precision-balance4 -

Analytical Weighing Balance, Commercial Weighing Scale, Computer Interface Weighing Scale, Counting Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, Jewellery Scale, Label Printing Scale, Laboratory Scale, Pharmacy weighing scale, Piece Counting Weighing Scale, Sansui Jewellery Scale, Sartorius Analytical Balance, Sartorius Weighing Balance, Waterproof Weighing Scale, Weighing Machine, weighing scale

Sartorius Entris® II Analytical Weighing Balance | Capacity 60 gm & 0.1 mg

Analytical Weighing Balance, Commercial Weighing Scale, Computer Interface Weighing Scale, Counting Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, Jewellery Scale, Label Printing Scale, Laboratory Scale, Pharmacy weighing scale, Piece Counting Weighing Scale, Sansui Jewellery Scale, Sartorius Analytical Balance, Sartorius Weighing Balance, Waterproof Weighing Scale, Weighing Machine, weighing scaleSartorius Entris® II Analytical Weighing Balance | Capacity 60 gm & 0.1 mg

Rated 5.00 out of 5(3)Sartorius Entris® II Analytical Weighing Balance Capacity 60 gm & 0.1 mg with Government Calibration Verification Certificates.

No matter what you’re weighing, the new Entris® II balance is always the right choice. Offering unrivaled value and backed by almost 150 years of German engineering expertise, the Entris® II comes in two product lines, so you can find the balance that meets your specific weighing needs.

Get Free Delivery & Installation of all Weighing Scale in Only Delhi NCR – Noida, Greater Noida, Ghaziabad, Delhi, Gurugram, and Meerut (Note* – UP Scales don’t provide delivery in outer Delhi NCR).

[caldera_form id=”CF5cbeab187482a”]

SKU: sartorius-entris-ii-analytical-weighing-balance-capacity-60-gm-0-1-mg -

Cas Weighing Scale, Commercial Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, Platform Weighing Scale, UP Scales, Weighing Machine, Weighing Machine With Printer, weighing scale

CAS – Industrial Bench Scale | Capacity 300 kg & 600 kg

Cas Weighing Scale, Commercial Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, Platform Weighing Scale, UP Scales, Weighing Machine, Weighing Machine With Printer, weighing scaleCAS – Industrial Bench Scale | Capacity 300 kg & 600 kg

Rated 5.00 out of 5(3)CAS – Industrial Bench Scale 300 kg & 600 kg with Government Passing, Stamping & Calibration Certificate. Same-day Installation in Noida, Greater Noida & Ghaziabad. For Booking Industrial Bench Scale Call us on 9899008683.

Our All weighing scales & Machines are Government approved for use in Commercial & Personal Use.Get Free Delivery & Installation of all Weighing Scale in Only Delhi NCR – Noida, Greater Noida, Ghaziabad, Delhi, Gurugram, and Meerut (Note* – UP Scales don’t provide delivery & installation in outer Delhi NCR).

[caldera_form id=”CF5cbeab187482a”]

SKU: cas-industrial-bench-scale -

Analytical Weighing Balance, Cas Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, Jewellery Scale, Laboratory Scale, UP Scales, Weighing Machine, weighing scale

High Performance Precision Balance – CAS | Micro Weighing Scale | Capacity 1500 gm & Readability 0.01 gm

Analytical Weighing Balance, Cas Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, Jewellery Scale, Laboratory Scale, UP Scales, Weighing Machine, weighing scaleHigh Performance Precision Balance – CAS | Micro Weighing Scale | Capacity 1500 gm & Readability 0.01 gm

Rated 4.67 out of 5(3)High-performance precision balance Micro-Weighing scale with superior performance measuring up to 150-6000 gm weight. The operating temperature is 5˚C – 40˚C. Therefore accurate measurement is possible in any workplace. Moreover, with its superior performance, various interfaces, and easy power charging, therefore efficient measure is possible. the High-performance precision balance Micro-Weighing scale will be taking on a new standard of Micro-Weighing Scale.

Get Free Delivery & Installation of all Weighing Scale in Only Delhi NCR – Noida, Greater Noida, Ghaziabad, Delhi, Gurugram, and Meerut (Note* – UP Scales don’t provide delivery & installation in outer Delhi NCR).

[caldera_form id=”CF5cbeab187482a”]

SKU: high-performance-precision-balance3 -

Commercial Weighing Scale, Computer Interface Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, Platform Weighing Scale, UP Scales, Weighing Machine, weighing scale

Heavy Duty Platform Weighing Scale 5 Ton | Platform Size (1200×1200 mm), (1500×2500 mm), (1800×3600 mm)

Commercial Weighing Scale, Computer Interface Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, Platform Weighing Scale, UP Scales, Weighing Machine, weighing scaleHeavy Duty Platform Weighing Scale 5 Ton | Platform Size (1200×1200 mm), (1500×2500 mm), (1800×3600 mm)

Rated 5.00 out of 5(4)Heavy Duty Platform Weighing Scale 5 ton with Calibration Certificate & Government Stamping from Weight & Measurement Department. One Year Warranty & One Day Free Delivery in Noida, Greater Noida & Ghaziabad. Our all Weighing Machine is Government Approved for use in Commercial & Personal Use. For Weighing Machine(Booking) Call 9899008683.

Get Free Delivery & Installation of all Weighing Scale in Only Delhi NCR – Noida, Greater Noida, Ghaziabad, Delhi, Gurugram, and Meerut (Note* – UP Scales don’t provide delivery & installation in outer Delhi NCR).

SKU: heavy-duty-platform-weighing-scale-5-ton -

Analytical Weighing Balance, Electronic Weighing Machine, Industrial Weighing Scale, Jewellery Scale, Laboratory Scale, Pharmacy weighing scale, UP Scales, Weighing Machine, weighing scale

Jewellery Weighing Scale – Precision Balances

Analytical Weighing Balance, Electronic Weighing Machine, Industrial Weighing Scale, Jewellery Scale, Laboratory Scale, Pharmacy weighing scale, UP Scales, Weighing Machine, weighing scaleJewellery Weighing Scale – Precision Balances

Rated 5.00 out of 5(3)Jewellery weighing scale Capacity 50 gm, 100 gm, 150 gm, 200 gm, 300 gm, 400 gm, 500 gm, 1 kg, 2 kg with calibration certificate, and Government stamping from Legal Metrology Department.

Free Same day delivery and Installation in Noida, Greater Noida, Ghaziabad & Delhi NCR. Our all weighing machine is approved by the legal metrology department for use in Commercial and Personal use.

Get Free Delivery & Installation of all Weighing Scale in Only Delhi NCR – Noida, Greater Noida, Ghaziabad, Delhi, Gurugram, and Meerut (Note* – UP Scales don’t provide delivery & installation in outer Delhi NCR).

[caldera_form id=”CF5cbeab187482a”]

SKU: jewellery-weighing-scale-precision-balances -

Analytical Weighing Balance, Commercial Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, Jewellery Scale, Laboratory Scale, mettler toledo jewellery scales, Pharmacy weighing scale, Sansui Jewellery Scale, Weighing Machine, weighing scale

Mettler Toledo Jewellery Scales

Analytical Weighing Balance, Commercial Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, Jewellery Scale, Laboratory Scale, mettler toledo jewellery scales, Pharmacy weighing scale, Sansui Jewellery Scale, Weighing Machine, weighing scaleMettler Toledo Jewellery Scales

Rated 5.00 out of 5(3)Mettler Toledo Jewelry Scales For laboratory, factory, jewelry shops, goldsmiths, etc. Capacity 1.2 g to 23200 gm, Readability 0.001 mg to 1 gm & Pan Size is 180 x 180 mm with Calibration Certificate & Government Stamping from Weight & Measurement Department. One Day Free Delivery in Noida, Greater Noida & Ghaziabad. Our all Weighing Machine are Government Approved for use in Commercial & Personal Use. For Weighing Machine(Booking) Call 9899008683

Mettler Toledo Jewelry Scales – JP and JS gold scales models feature robust and accurate MonoBloc gold weighing technology which is made in Switzerland with internal weight, rapid settling, and fast response time even in tough conditions.

Get Free Delivery & Installation of all Weighing Scale in Only Delhi NCR – Noida, Greater Noida, Ghaziabad, Delhi, Gurugram, and Meerut (Note* – UP Scales don’t provide delivery & installation in outer Delhi NCR).

SKU: mettler-toledo-jewellery-scales -

Commercial Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, Platform Weighing Scale, UP Scales, Weighing Machine, Weighing Machine For Shops, weighing scale

Electronic Weighing Machine Capacity 300 kg

Commercial Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, Platform Weighing Scale, UP Scales, Weighing Machine, Weighing Machine For Shops, weighing scaleElectronic Weighing Machine Capacity 300 kg

Rated 5.00 out of 5(3)Electronic Weighing Machine For Shops 300 kg with Calibration Certificate & Government Stamping from Weight & Measurement Department. One Year Warranty & One Day Free Delivery in Noida, Greater Noida & Ghaziabad. Our all Weighing Machine is Government Approved for use in Commercial & Personal Use. For Weighing Machine(Booking) Call 9899008683.

Get Free Delivery & Installation of all Weighing Scale in Only Delhi NCR – Noida, Greater Noida, Ghaziabad, Delhi, Gurugram, and Meerut (Note* – UP Scales don’t provide delivery & installation in outer Delhi NCR).

SKU: electronic-weighing-machine-for-300kg -

Commercial Weighing Scale, Crane Scale, Electronic Weighing Machine, Hanging Scale, Industrial Weighing Scale, UP Scales, Weighing Machine, weighing scale

Hanging Scale 2 ton

Commercial Weighing Scale, Crane Scale, Electronic Weighing Machine, Hanging Scale, Industrial Weighing Scale, UP Scales, Weighing Machine, weighing scaleHanging Scale 2 ton

Rated 5.00 out of 5(3)Hanging Scale 2 ton for Cranes or use it as Hanging with Calibration Certificate & Government Stamping from Weight & Measurement Department. One Year Warranty & One Day Free Delivery in Noida, Greater Noida & Ghaziabad. Our all Weighing Machine is Government Approved for use in Commercial & Personal Use. For Weighing Machine(Booking) Call 9899008683.

Get Free Delivery & Installation of all Weighing Scale in Only Delhi NCR – Noida, Greater Noida, Ghaziabad, Delhi, Gurugram, and Meerut (Note* – UP Scales don’t provide delivery & installation in outer Delhi NCR).

SKU: hanging-scale-2-ton -

Commercial Weighing Scale, Computer Interface Weighing Scale, Crane Scale, Electronic Weighing Machine, Hanging Scale, Industrial Weighing Scale, UP Scales, Waterproof Weighing Scale, Weighing Machine, Weighing Machine With Printer, weighing scale

Crane Scale 1 ton, 2 ton, 3 ton, 5 ton With Printer | OCS Crane Scale & Hanging Scale

Commercial Weighing Scale, Computer Interface Weighing Scale, Crane Scale, Electronic Weighing Machine, Hanging Scale, Industrial Weighing Scale, UP Scales, Waterproof Weighing Scale, Weighing Machine, Weighing Machine With Printer, weighing scaleCrane Scale 1 ton, 2 ton, 3 ton, 5 ton With Printer | OCS Crane Scale & Hanging Scale

Rated 5.00 out of 5(3)Electronic Crane scale with capacity 1 ton, 2 ton, 3 ton & 5 ton with Government calibration verification certificate and Stamping. This electronic weighing scale has a wireless remote control with a distance of more than 1 Km.

Get Free Delivery & Installation of all Weighing Scale in Only Delhi NCR – Noida, Greater Noida, Ghaziabad, Delhi, Gurugram, and Meerut (Note* – UP Scales don’t provide delivery in outer Delhi NCR).

[caldera_form id=”CF5cbeab187482a”]

SKU: crane-scale-with-printer-ocs2 -

Cas Weighing Scale, Commercial Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, OHAUS Weighing Balance, Platform Weighing Scale, Weighing Machine, weighing scale

Platform Weighing Scale 300 kg

Cas Weighing Scale, Commercial Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, OHAUS Weighing Balance, Platform Weighing Scale, Weighing Machine, weighing scalePlatform Weighing Scale 300 kg

Rated 5.00 out of 5(3)Industrial Weighing Scales/Platform Weighing Scale/Heavy Duty Weighing Scale 300kg with Calibration Certificate & Government Stamping from Weight & Measurement Department. One Year Warranty & One Day Free Delivery in Noida, Greater Noida & Ghaziabad. Our all Weighing Machine is Government Approved for use in Commercial & Personal Use. For Weighing Machine(Booking) Call 9899008683.

Get Free Delivery & Installation of all Weighing Scale in Only Delhi NCR – Noida, Greater Noida, Ghaziabad, Delhi, Gurugram, and Meerut (Note* – UP Scales don’t provide delivery & installation in outer Delhi NCR).

SKU: platform-weighing-scale-300kg -

Commercial Weighing Scale, Computer Interface Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, Platform Weighing Scale, Weighing Machine, Weighing Machine For Shops, weighing scale

Weighing Scale | Capacity 15 kg, 30 kg, 60 kg & Readability 0.5 gm, 1 gm, 2 gm

Commercial Weighing Scale, Computer Interface Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, Platform Weighing Scale, Weighing Machine, Weighing Machine For Shops, weighing scaleWeighing Scale | Capacity 15 kg, 30 kg, 60 kg & Readability 0.5 gm, 1 gm, 2 gm

Rated 5.00 out of 5(3)Weighing scale capacity 15 kg, 30 kg, 60 kg, and accuracy 0.5 gm, 1 gm, 2 gm with calibration certificate and Government stamping by Legal Metrology Department and weight & Measurement Department. Our all weighing machine is approved by the weight & Measurement department for use in commercial and personal use.

Get Free Delivery & Installation of all Weighing Scale in Only Delhi NCR – Noida, Greater Noida, Ghaziabad, Delhi, Gurugram, and Meerut (Note* – UP Scales don’t provide delivery & installation in outer Delhi NCR).

[caldera_form id=”CF5cbeab187482a”]

SKU: weighing-scale2 -

Commercial Weighing Scale, Computer Interface Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, Platform Weighing Scale, UP Scales, Weighing Machine, Weighing Machine For Shops, Weighing Machine With Printer, weighing scale

Platform Weighing Scale | Capacity 1000 kg, e value 100 gm | Platform Size 900×900 mm

Commercial Weighing Scale, Computer Interface Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, Platform Weighing Scale, UP Scales, Weighing Machine, Weighing Machine For Shops, Weighing Machine With Printer, weighing scalePlatform Weighing Scale | Capacity 1000 kg, e value 100 gm | Platform Size 900×900 mm

Rated 5.00 out of 5(3)UP Scales manufacture made in India platform weighing scale for shops and Industrial use, Platform weighing scale capacity 1000 kg and e value 100 gm with heavy-duty structure and platform size of 900×900 mm. Our all platform weighing scale is approved by Legal Metrology Department (Weight & Measurement Department) and OIML to use in Commerical, Industrial, and Personal use, our Platform weighing scale also comes with a Government calibration verification certificate and stamping.

Get Free Delivery & Installation of all Weighing Scale in Only Delhi NCR – Noida, Greater Noida, Ghaziabad, Delhi, Gurugram, and Meerut (Note* – UP Scales don’t provide delivery in outer Delhi NCR).

[caldera_form id=”CF5cbeab187482a”]

SKU: platform-weighing-scale-capacity-1000-kg-100-gm -

Cas Weighing Scale, Commercial Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, Platform Weighing Scale, UP Scales, Weighing Machine, weighing scale

Industrial Weighing Scale 100kg Capacity – CAS

Cas Weighing Scale, Commercial Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, Platform Weighing Scale, UP Scales, Weighing Machine, weighing scaleIndustrial Weighing Scale 100kg Capacity – CAS

Rated 5.00 out of 5(3)Industrial Platform Weighing Scale – CAS Capacity 100 kg with Government passing & Stamping and with various variable platform size 300 x 300 mm, 400 x 400 mm, 500 x 500 mm with Readability of 0.100 gm. Industrial Platform weighing scale 100 kg with Calibration certificate, for Booking call us on 9899008683. Our all weighing machine is Government approved for use in Commercial and Personal use.

Get Free Delivery & Installation of all Weighing Scale in Only Delhi NCR – Noida, Greater Noida, Ghaziabad, Delhi, Gurugram, and Meerut (Note* – UP Scales don’t provide delivery & installation in outer Delhi NCR).

[caldera_form id=”CF5cbeab187482a”]

SKU: industrial-weighing-scale-100kg-capacity-cas -

Commercial Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, UP Scales, Weighing Machine, Weighing Machine For Shops, weighing scale

Electronic Weighing Machine For Shop 30 kg (Contech)

Commercial Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, UP Scales, Weighing Machine, Weighing Machine For Shops, weighing scaleElectronic Weighing Machine For Shop 30 kg (Contech)

Rated 5.00 out of 5(3)Electronic Weighing Machine For Shops 30kg (Contech) with Calibration Certificate & Government Stamping from Weight & Measurement Department. One Year Warranty & One Day Free Delivery in Noida, Greater Noida & Ghaziabad. Our all Weighing Machine is Government Approved for use in Commercial & Personal Use. For Weighing Machine(Booking) Call 9899008683

[caldera_form id=”CF5cbeab187482a”]

SKU: electronic-weighing-machine-for-shops-30kg-contech -

Counting Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, Label Printing Scale, Platform Weighing Scale, Price Computing Scale, UP Scales, Weighing Machine, Weighing Machine For Shops, weighing scale

Platform Weighing Scale Capacity 2000 kg – UP Scales

Counting Weighing Scale, Electronic Weighing Machine, Industrial Weighing Scale, Label Printing Scale, Platform Weighing Scale, Price Computing Scale, UP Scales, Weighing Machine, Weighing Machine For Shops, weighing scalePlatform Weighing Scale Capacity 2000 kg – UP Scales

Rated 4.60 out of 5(5)Platform weighing scale 2000 kg capacity is specially designed for Industries & Shops. This platform scale is manufactured by UP Scales and gives complete assurance of the durability of Platform weighing scale and UP Scales manufactured this scale in two different body designs, first come in Complete metal body and second variant in Stainless steel body. This platform weighing scale of 2000 kg is one of its own kind this platform scale has three weighing scale features in one – Weighing, Counting, Computing & litre Conversion.

Our platform weighing scale 2000 kg is approved by the legal metrology department and Weight & Measurement department for use in Commercial and Personal Use. For more information or booking about Platform weighing scale 2000 kg, you can also call us on 9899008683.

Get Free Delivery & Installation of all Weighing Scale in Only Delhi NCR – Noida, Greater Noida, Ghaziabad, Delhi, Gurugram, and Meerut (Note* – UP Scales don’t provide delivery & installation in outer Delhi NCR).

[caldera_form id=”CF5cbeab187482a”]

SKU: platform-weighing-scale-capacity-2000kg -